Hirata Corporation (Japan)

"Hirata's all-electric transport system that is friendly to people and the environment"

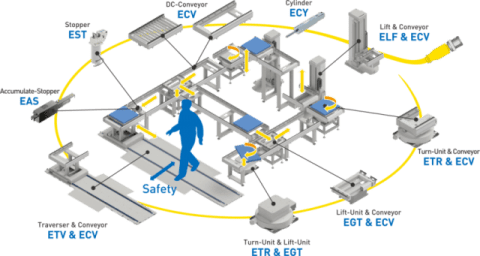

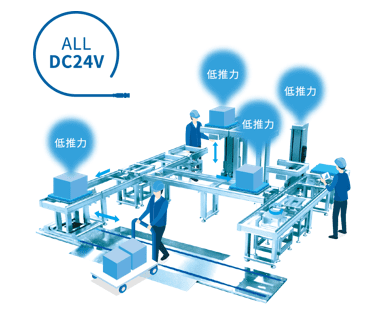

Based on its track record in a variety of industrial fields, Hirata provides airless and safe production equipment by achieving all-electric transport in the "transportation" system that is the basis of production equipment, allowing factories to operate without placing a burden on the environment. We will contribute to the realization.

Based on its track record in a variety of industrial fields, Hirata provides airless and safe production equipment by achieving all-electric transport in the "transportation" system that is the basis of production equipment, allowing factories to operate without placing a burden on the environment. We will contribute to the realization.

Hirata Kiko Co., Ltd.: Company information

《Hirata's eco electric series》

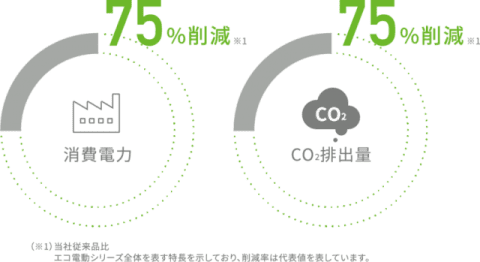

- Contributing to reducing CO2 emissions

- Can be fully electric with no need for air equipment

- Safe and low thrust allows collaborative work with people

Please contact the distributor Taihei Boeki for details.

(Industrial Machinery Section)

Achieving carbon neutrality with all-electric transfer lines

[Understand in 1 minute! ] Hirata's eco electric series

[Hide]

- 1.Hirata's all-electric transport system is friendly to people and the environment.

- 2.Product list

- Electric DC conveyor [ECV50C]

- Electric DC roller conveyor [ECV50C-RC]

- Electric stopper [EST32/50/80]

- Electric cylinder [ECY40]

- Electric traverser [ETV600]

- Electric turn unit [ETR90/180]

- Electric slider ball screw drive type [ESL30/ESL6TV], belt drive type [ESLV20]

- Balance stopper [EAS100/200]

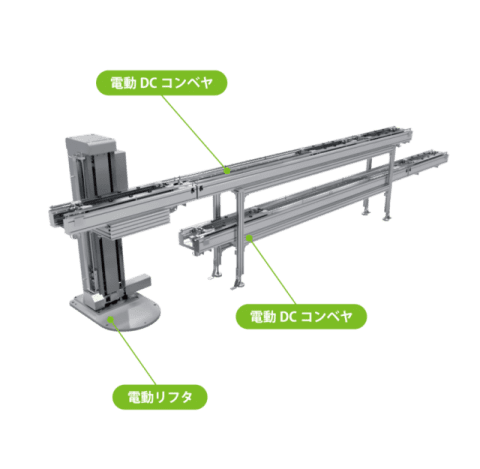

- Electric lifter [ELF46]

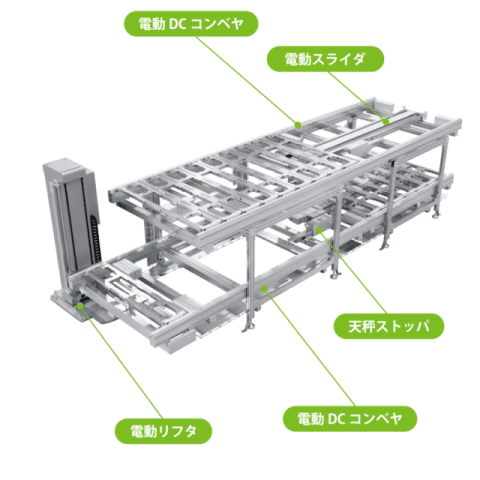

- system products

Hirata's all-electric transport system is friendly to people and the environment.

eco electric series

《Features of Eco Electric Series》

1. Airless and environmentally friendly: Contributing to the realization of carbon neutrality

Approximately 25% of the electricity used in the factory is for compressors.

The Eco Electric Series reduces power consumption as it does not require air equipment.

It also contributes to CO2 reduction.

2. All DC24V

Running costs can be reduced because the transfer line can be fully electric without the need for air equipment.

3. Low thrust(*1)safe in

The eco-electric series has low thrust, so safety equipment (*2) is not required.

Able to work collaboratively with people.

*1: Low thrust

A safe, weak force that causes equipment to react and move in the event of a collision or other emergency.

*2: Safety equipment

Equipment such as safety fences and light curtains that prevent people from coming into contact with equipment and causing injury.

Product list

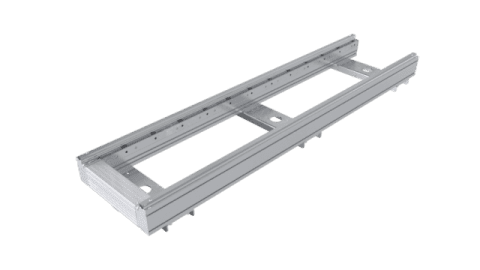

Electric DC conveyor [ECV50C]

A compact and easy-to-maintain friction conveyor with a drive unit housed within the frame.

It has a good reputation in production lines in the automobile industry, where people assemble parts while the product is flowing.

It includes all the equipment necessary for driving, such as a dedicated motor, control board, and speed channel [CH], and is also standard equipped with guide rails to support stable pallet transport.

A wide variety of specially designed options.

It includes all the equipment necessary for driving, such as a dedicated motor, control board, and speed channel [CH], and is also standard equipped with guide rails to support stable pallet transport.

A wide variety of specially designed options.

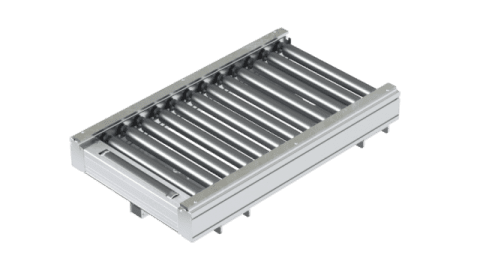

Electric DC roller conveyor [ECV50C-RC]

It can transport container boxes, cardboard boxes, etc. in a variety of shapes (pallets with cutouts on the sides can also be transported).

A compact and easy-to-maintain friction roller conveyor with a drive unit housed within the frame.

It has a good reputation in production lines in the automobile industry, where people assemble parts while the product is flowing.

It includes all the equipment necessary for driving, such as a dedicated motor, control board, and speed channel [CH], and is also equipped as standard with guide rails to support stable pallet transport.

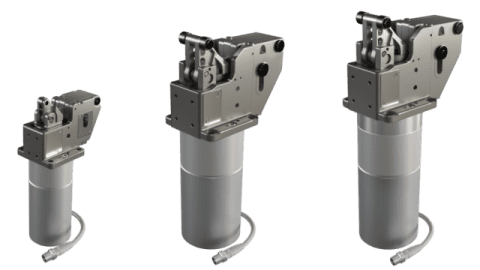

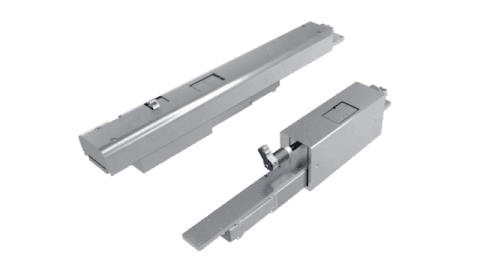

Electric stopper [EST32/50/80]

A solenoid stopper that stops the workpiece (pallet).

The stopper lever lowers in 0.2 seconds, dramatically improving takt time.

The operating part and the part that receives impact are separate mechanisms, making it less likely to be damaged.

There is little exposure of the moving parts, reducing the risk of fingers getting caught.

The operating part and the part that receives impact are separate mechanisms, making it less likely to be damaged.

There is little exposure of the moving parts, reducing the risk of fingers getting caught.

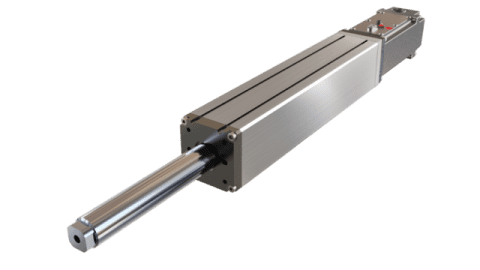

Electric cylinder [ECY40]

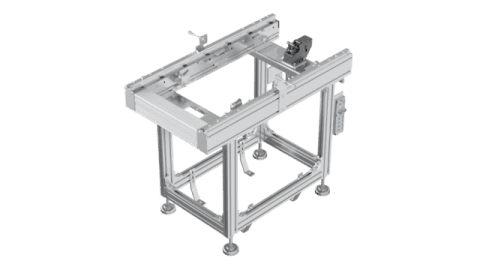

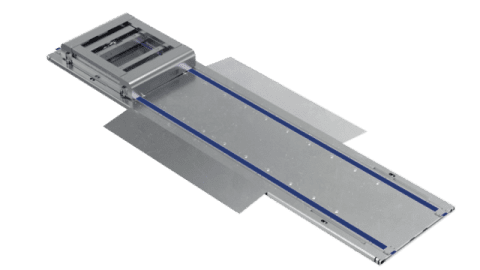

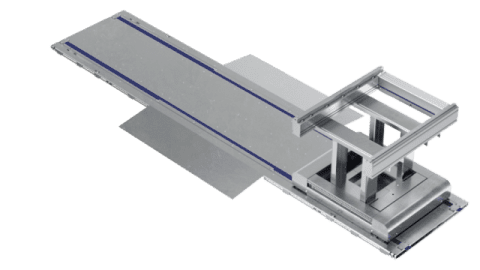

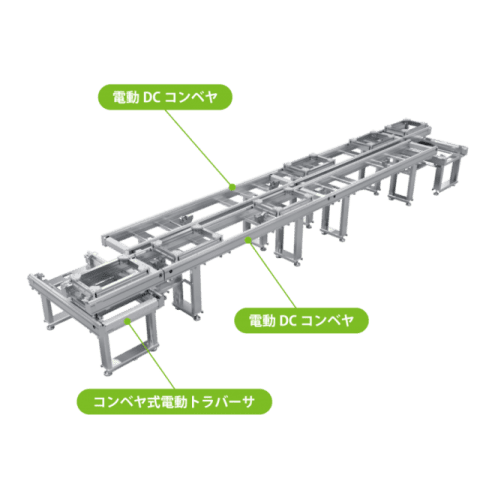

Electric traverser [ETV600]

By sliding the conveyor mounted on the top of the electric traverser, people and trolleys can safely enter and exit on the low-floor rail (approximately 40 mm) without stopping conveyance.

By installing a slope (optional), people and trolleys can enter and exit smoothly.

By installing a slope (optional), people and trolleys can enter and exit smoothly.

Available in two types: standard payload type (ETV600: 280kg) and high payload type (ETV600H: 380kg), with a maximum stroke of 2mm.

(The figure below is an example with ECV50C installed)

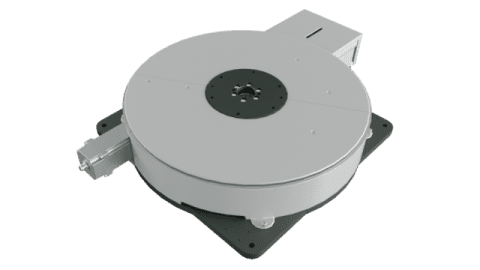

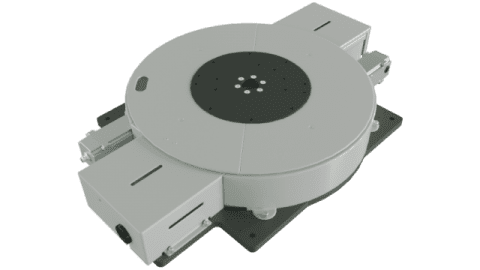

Electric turn unit [ETR90/180]

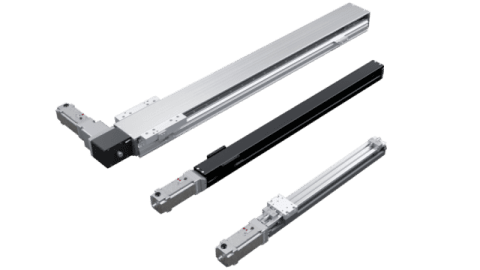

Electric slider ball screw drive type [ESL30/ESL6TV], belt drive type [ESLV20]

■Ball screw drive type [ESL30/ESL6TV]

Ball screw driven electric slider that is driven only by DC24V and does not require a dedicated driver.

ESL30: 200mm to 700mm stroke compatible

ESL6TV: 721mm~920mm stroke compatible

By focusing on the functions required on the production line and eliminating waste, we have made it possible to eliminate troublesome settings and adjustments.

■Belt drive type [ESLV20]

Belt-driven electric slider that is powered only by DC24V and does not require a dedicated driver.

ESLV20: 220mm~2020mm stroke compatible

Ball screw driven electric slider that is driven only by DC24V and does not require a dedicated driver.

ESL30: 200mm to 700mm stroke compatible

ESL6TV: 721mm~920mm stroke compatible

By focusing on the functions required on the production line and eliminating waste, we have made it possible to eliminate troublesome settings and adjustments.

■Belt drive type [ESLV20]

Belt-driven electric slider that is powered only by DC24V and does not require a dedicated driver.

ESLV20: 220mm~2020mm stroke compatible

Balance stopper [EAS100/200]

A balance stopper that is driven only by DC24V and does not require a dedicated controller.

It is possible to stop the pallets on the conveyor and cut out one pallet at a time from a stock of multiple pallets.

Cutting is done by rotating the two attachments at the front and back, so two or more sheets will not be cut out at the same time.

EAS100: Allowable amount of transported material ~225kg

EAS200: Allowable amount of transported material ~740kg

Cutting is done by rotating the two attachments at the front and back, so two or more sheets will not be cut out at the same time.

EAS100: Allowable amount of transported material ~225kg

EAS200: Allowable amount of transported material ~740kg