BARTEC Top Holding GmbH (Germany)

BARTEC Group

BARTEC (Germany)

A highly specialized global manufacturer of highly safe equipment and systems used in explosive gas and dust environments.

Acquired ISO9001/14001/50001 certification

BARTEC excels in chemical plants, the oil and gas industry, mines, ships and offshore rigs, making a significant contribution to improving safety and efficiency in the handling of hazardous materials.

Authorized distributor: Shimada Electric Co., Ltd.

(Specialized manufacturer of explosion-proof electrical equipment, ISO9001/14001 certified)

Cooperating agency: Taihei Boeki Co., Ltd.

Please contact Taihei Boeki for details. (Industrial Machinery Section)

[Hide]

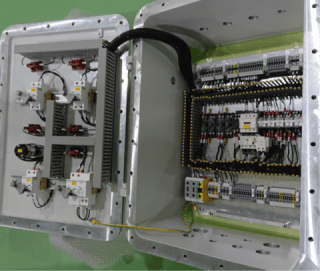

Explosion-proof panel

EJB series (hydrogen compatible explosion-proof panel)

- Certification number: CML 21JPN11337X

- Explosion-proof structure: Flameproof/intrinsically safe explosion-proof structure

- Marking: Ex db[ia IIA, IIB, IIC Ga] IIB+H2 T6…T3, IP66

- Of the IIC gas groups, only hydrogen is supported

- Maximum size: 660 x 960 x 462

GUB series (hydrogen compatible explosion-proof panel)

- Certification number: CML 22JPN1055X

- Explosion-proof structure: Flameproof/intrinsically safe explosion-proof structure

- Marking: Ex db [ia/ib IIA/IIB/IIC Ga] IIC T6…T3, IP66

- Compatible with all gases

- Maximum size: without window 600 x 600 x 382 / with window 420 x 420 x 281

Product features

Common to EJB/GUB series

- Standard material: aluminum, stainless steel also available

- Standard coating: Epoxy powder, gray (RAL9006), 80μm

- Storeable electrical equipment/terminals: No restrictions on types

- Intrinsically safe barrier: can be installed

- Primary battery: Can be installed

Points to note/restrictions

Common to EJB/GUB series

- Stored electrical equipment/terminals: No restrictions on types, but restrictions on heat output

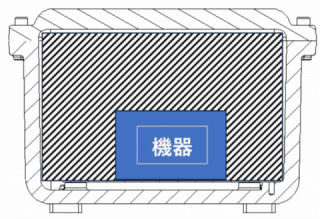

- Requires free space of 40% or more in cross-sectional area

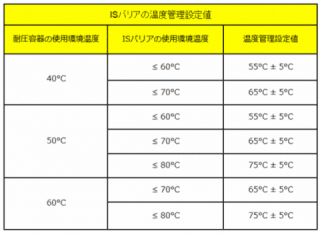

- Intrinsically safe barrier: Can be installed, but temperature control may be required

- Primary battery: Must be within 1% of total volume

- Secondary battery: In principle, currently not possible (possible with batteries made by SAFT (France), but an interlock circuit is required)

- Products that emit laser: Cannot be installed

Heat limitation and free space

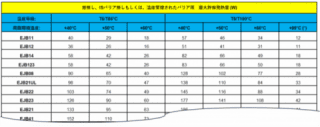

- Limit values are stated in the IECEx certificate.

- The limit value changes depending on the ambient temperature, the presence or absence of a barrier, and the presence or absence of a window.

- If the temperature of the barrier is controlled as shown below (Figure 2), the total calorific value will not change.

- If temperature is not controlled, the amount of heat generated will be greatly limited.

- Controlled by thermometer (thermistor, etc.) + temperature controller, etc.

- The black hatched area should be 3% or more of the total cross-sectional area as shown below (Figure 40).

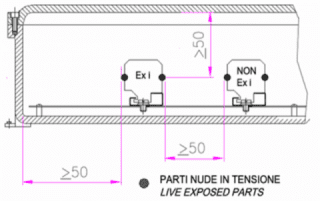

separation distance

- Non-intrinsically safe devices: Requires a distance of 15mm or more from the inner wall of the housing

- Intrinsically safe equipment: Requires a distance of 50 mm or more from the inner wall of the housing.

- Between intrinsically safe and non-intrinsically safe devices: distance of 50mm or more required

- Intrinsically safe and non-intrinsically safe wires: separated by duct

What is separation distance? A certain distance that should be placed between two or more objects, mainly set from a safety perspective.

Points to note/supplements

- The calorific value listed on the certificate is a value based on explosion-proof safety standards, and is not an electrically guaranteed value.

- Separation distance is also a regulation for explosion protection, and if there is a regulation for each electrical item, it must be followed.

Example) Inverter:

It states that for heat dissipation, a space of 10 cm above and 5 cm on the left and right must be provided.

- When manufacturing as an ATEX product, it is necessary to use CE-marked equipment and wires (DoC will not be issued).

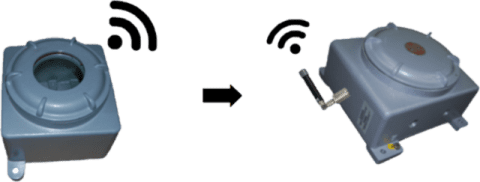

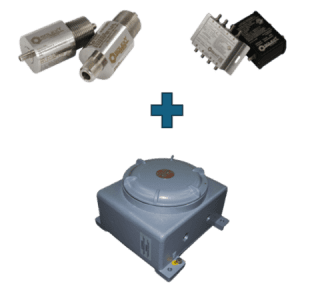

Explosion-proof panel + SOLEXY antenna barrier (wireless)

When combined with SOLEXY,Easily make non-explosion-proof products explosion-proof!!

EJB series supports [Exd II B+H2], GUB series supports [Exd II C]

(Domestic explosion proof certified)

- Explosion-proof containers (EJB, GUB series) allow for quick and simple storage of electrical equipment and terminals.

- No restrictions on the types of devices and terminals that can be stored

- Various types of electronic/electrical equipment and wireless equipment can be installed as long as the amount of heat dissipation and free space are within limits.

- Transparent windows can be installed and indicators can be visually checked.

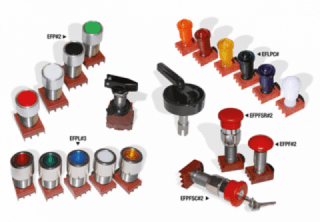

- Indicator lights, push buttons, changeover switches, and external handles for MCB/MCCB/disconnectors can be installed on the panel surface.

- Intrinsically safe explosion-proof barriers can also be installed by considering temperature control.

Within the above range, no additional application for explosion proof certification is required. This greatly contributes to reducing development time and costs.

The future of the explosion-proof industry opened up by digitalization

Due to labor shortages (population decline) and work style reforms that will be revised from April 2024, there will be a greater need than ever to improve labor productivity. One of the solutions to this problem is thought to be the widespread promotion of digital/wireless devices.

This will make it easier for non-explosion-proof equipment manufacturers who have previously been unable to enter the explosion-proof industry, and is expected to rapidly promote the introduction of cutting-edge systems.

Additionally, explosion-proof equipment in Japan is far behind the non-explosion-proof market, but with the EJB/GUB+antenna barrier, the adoption of cutting-edge technology is expanding, and AI control will become possible relatively easily. It is assumed that

Based on this, it is expected that BARTEC and SOLEXY's technological capabilities will further contribute to solving these issues in the future.

Catalogues

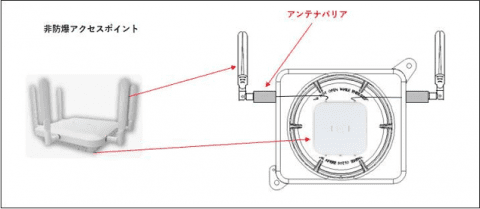

Explosion-proof access point It is possible to create a WiFi wireless environment within the factory premises in an explosion-proof environment!

|

MC93ex‑NI mobile computer (July 2024: Scheduled to obtain domestic explosion proof certification)

|

MC93ex‑NI mobile computer accessories (Accessories for use in explosion-proof areas)

(Accessories for use in non-explosion areas)

|