AMDP SAS (France)

AMDP (France)

Total manufacturer of spot welding peripherals

Total manufacturer of spot welding peripherals

ISO9001 certification

AMDP provides a wide range of high quality products to the automotive industry for use in spot welding electrode polishing and replacement.

We have always increased the value and performance of our products to meet the changing needs of the automobile industry. With more than 30 years of experience and achievements, we will continue to supply new chip dressers to the market in order to improve productivity by polishing electrodes and improving replacement efficiency.

For details, please contact our import agent, Taihei Boeki. (Industrial Machinery Section)

Spot welding

Product list AMDP

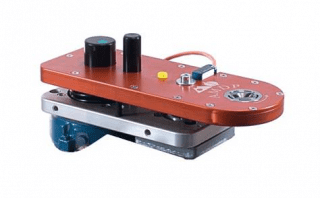

Chip Dresser

Easy integration, high speed rotation (640rpm), excellent followability, and the characteristics of the cutter do not require air blow. Polishing time can be reduced to less than 1 second. Maintenance-free. It can be mounted on a sturdy stand. Please contact us for the specifications of the control panel.

Overview

Each dresser can be mounted on a stationary or height-adjustable stand.

Applications that make up the unit

- Motor that rotates the cutter

- Head that fixes and moves the cutter

- Electric control unit

- Cutter rotation controller

- Height-adjustable shavings receiver

The dresser is designed to be used with a robot control panel attached. We also have an independent control panel for manual welding guns.

Advantage

- New head-high speed

- Smooth and high-speed installation and removal of the cutter

- Easy to combine

- Head orientation can be adjusted in 90° increments

- Compact head for any type of welding gun

- Flexible combinations are possible for each application

- Recommended welding pressure applied to the cutter: 80-150daN (depending on the type of electrode and welding gun)

|

Cutter

The 2 blades prevent misalignment during polishing and realizes high-quality electrode polishing. Since the shavings are pushed out by centrifugal force, there is no clogging and there is no need to blow with air. There is no center pin, and the dimensions are minimal. It can be used with any chip dresser regardless of the manufacturer. It minimizes vibration and blurring and maximizes the life of the electrodes. We support both HSS and carbide materials. We design and manufacture cutters that match your electrode drawings.

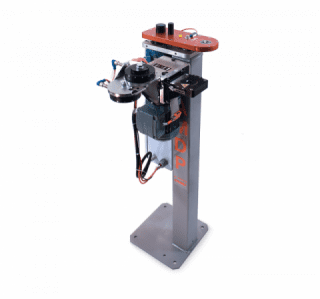

Swing arm

By making the motor position of the dresser a unique separate type, the arm movement is smoother and faster. It has excellent stability and can eliminate vibration and misalignment of the dresser. It also features a wide arm adjustment range. Please contact us for the specifications of the control panel.

Overview

The dresser mounted on the electric swing arm is a circular motion type electrode grinding machine.

Component parts

- Electric motor rotary table with built-in gearbox

- The chip dress head can be mounted (adjustable between 65° and 180°) in 360 positions around the swing arm

- Electric motor that rotates the cutter

- The dress head is fixed to an arm with a length of 600, 800, 1000 mm (please contact us if you have any other desired length)

- Electric control unit

- Cutter rotation detection controller

- Controller x, y, z direction

- Angle position of dress head

- Three-stage current supply

Advantage

- Power is supplied to only one place

- One swing arm for all applications (parallel, vertical, tilt)

- Compact design swing arm

- Simplified installation with various adjustment widths

- Adaptability and flexibility that can be used in other applications

- Quickly attach and remove the cutter to the dresser

- Compact dresshead capable of polishing all types of welding guns

- Recommended pressure value for polishing: 80-150daN (depending on gun and electrode type)

|

Ultimate combination

It has a compact structure that eliminates waste and is easy to integrate. Product performance and benefits are the same as regular AMD P chip exchanges. Achieves a quick electrode replacement cycle. The electrodes can be removed and replaced in a simple way.

Overview

Ultimate Combi is a machine that combines a tip dresser and a tip exchange. This machine will be built into the white body cell to improve your productivity and reliability. It can be installed both horizontally and vertically. These guns are compatible with any size and strength.

Features

Features

The AMDP chip exchange is a unit that combines a chip remover and a mounting machine. The robot approaches the electrode of the remover (patented) and removes the electrode cap by rotating at 80° or less. These correspond to both the upper and lower electrodes. The external unit can secure a simple trajectory between robots, and the replacement of electrode chips can be suppressed in just 15 seconds or less.

|

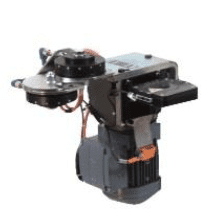

Ultimate changer

There is a stand

Compact and easy line formation is possible with or without a stand. It can be combined with the AMDP chip exchange on the same line. High-speed tip replacement in just 1 seconds per cycle greatly improves productivity. Installation and monitoring is also very easy.

Please contact us for the specifications of the control panel.

Please contact us for the specifications of the control panel.

No stand

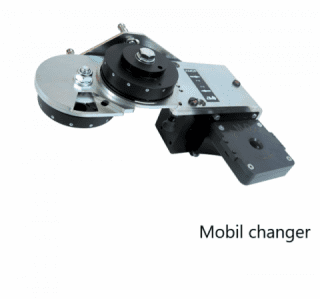

Ultimate Mobile Changer

The included air motor weighs less than 10 kg and can be easily integrated into your gripper.

Like the Ultimate Combination, it is a patented proprietary technology.

Chip replacement cycles can be reduced in less than 15 seconds, significantly increasing BIW cell productivity.

Installation and monitoring is also very easy.

No control panel is required.

Installation and monitoring is also very easy.

No control panel is required.

Tip exchange unit

We recommend the introduction of a tip replacement unit to further improve productivity.

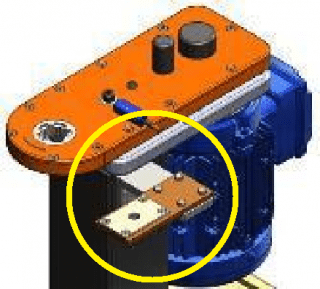

Mechanical combination

Install on the AMDP chip dresser.

We have adopted more than 10,000 units worldwide.

Easy to combine.

By operating with a robot, a tip exchange cycle of only 30 seconds is realized.

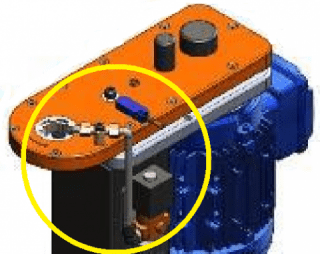

Mechanical mobile changer

No power supply is required to install it in your gripper.

Detected by three sensors.

It has a tip replacement cycle of about 30 seconds and is also excellent in durability.

Detected by three sensors.

It has a tip replacement cycle of about 30 seconds and is also excellent in durability.

Dressing bench

It is possible to polish as many as 8,000 electrodes per day.

Supports both manual and auto cycles.

Comes with a stand for hand-held welding guns.

Supports both manual and auto cycles.

Comes with a stand for hand-held welding guns.

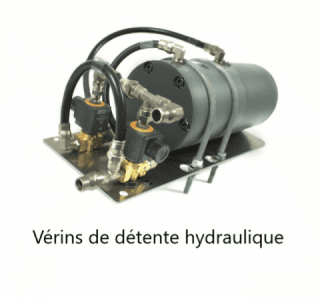

Water pumping cylinder

It eases the burden on the cooling water circuit before replacing the electrodes.

Increases safety within the cell and reduces risk and corrosion problems.

Compact and easy integration is possible.

Compact and easy integration is possible.

For air cylinders and energy-free solutions (Patented)Please contact us for more information.

Pneumatic handheld device

(Welding gun: when closed)

It is the most powerful device on the market and dresses both electrodes while closing the welding gun with a cutter. It has a compact and durable full aluminum body and uses the same cutter as all other products.

Check the ability of the handheld weld gun to close without starting the weld sequence.

Pneumatic handheld device

(Welding gun: when open)

It is designed to be lightweight so that the electrodes can be dressed one after another, and with its own AMDP guide unit, it is possible to weld lenses in parallel with both electrodes.

W Gun Array Kit

Always control the good alignment of the gun before and after electrode replacement polishing.

Increase BIW cell control with a simple solution.

Blowing kit

In rare cases, it may be necessary to blow shavings.

A normal AMDP blade does not require any blow structurally (because the centrifugal force during polishing automatically ejects shavings).

A normal AMDP blade does not require any blow structurally (because the centrifugal force during polishing automatically ejects shavings).