ELCo Enterprises, Inc. (USA)

Elco (USA)

Global manufacturer of arc welding equipment

ISO9001 certification

Elco Wire Wizard (Wire Wizard®) products for arc welding have a wide range of very unique and distinctive items.

We propose various solutions to the problems of wire feedability in arc welding and measures against spatter, and contribute to the reduction of maintenance man-hours on the production line and the improvement of welding quality.

[Hide]

- 1.Product list ELCO

- High performance welding torch and peripheral parts “Power Ball®”

- Flexible conduit for feeding arc welding wire

- Guide module

- Wire feeding assist device "Feed Assist"

- Wire straightener

- Welded wire continuous supply system

- Pack peripheral accessories

- Spatter adhesion preventive liquid "Blue Magic ®"

- Torch nozzle cleaning station

- Submerged arc welding

- inert gas saver

Arc welding

This is a pick-up catalog of products specialized for aluminum welding. WIRE WIZARD® Solutions for aluminum welding We offer solutions such as reducing friction in aluminum wire feeding, parts surrounding the torch, and preventing spatter adhesion.

|

Product list ELCO

High performance welding torch and peripheral parts “Power Ball®”

“Powerball” high performance welding torch and peripheral parts Wire Wizard's "Power Ball" torch peripheral parts product group can be expected to achieve performance that overturns conventional welding performance.

|

Flexible conduit for feeding arc welding wire

The world's highest quality arc welded wire feeding flexible conduit with extremely low friction resistance and outstanding durability. It improves various welding defects caused by wire feeding, and greatly reduces extra maintenance such as accidental downtime and associated work after work. You can choose from three series to suit your application.

|

Guide module

Guide module to improve the feedability of welded wires By simply attaching to the feed path and curved part of the arc welded wire, the frictional resistance of the wire is reduced, and the effects of dramatic improvement of welding defects, improvement of welding quality, reduction of spatter, reduction of maintenance, cost reduction, etc. are realized.

|

Wire feeding assist device "Feed Assist"

It assists the feeding by the wire feeder, improves various welding defects caused by the feeding property, and at the same time enables the long-distance feeding of the wire. Since it is driven by air, it can be used simply by connecting compressed air. No need to set synchronization with the wire feeder, and you can easily build a push-pull system.

|

Wire straightener

Wire Wizard (Wire Wizard®) Has four types of wire straighteners that can straighten and recast all types of wires.

The structure with an aluminum body is the lightest type of orthodontic appliance in the industry. All models have a fine adjustment scale with a tension knob on the front for easy wirecast adjustment. We also have a wide range of connector and inlet connectors, which can be used in various applications. |

Welded wire continuous supply system

It is a system that connects the wire end of the existing wire pack and the wire start end of the newly prepared pack by resistance butt welding in advance, and supplies the wire continuously non-stop. Butt welding and deburring of joints are simple and easy for anyone. The line downtime when replacing the wire pack is virtually zero.

|

Pack peripheral accessories

We have various accessories for the purpose of "pursuit of ease of use" and "labor saving". It is a product group that contributes to pack wire management, improved maintainability, and improved wire feeding. |

Spatter adhesion preventive liquid "Blue Magic ®"

|

Torch nozzle cleaning station

High speed, simple, easy installation with air piping only By simply inserting the welding torch, the reamer of spatter adhering to the inside of the nozzle can be removed and the non-spatter liquid spray can be performed "at the same time". Welding quality is stabilized, production efficiency is improved, and the cost of consumables such as chips and nozzles is reduced by automating spatter removal.

|

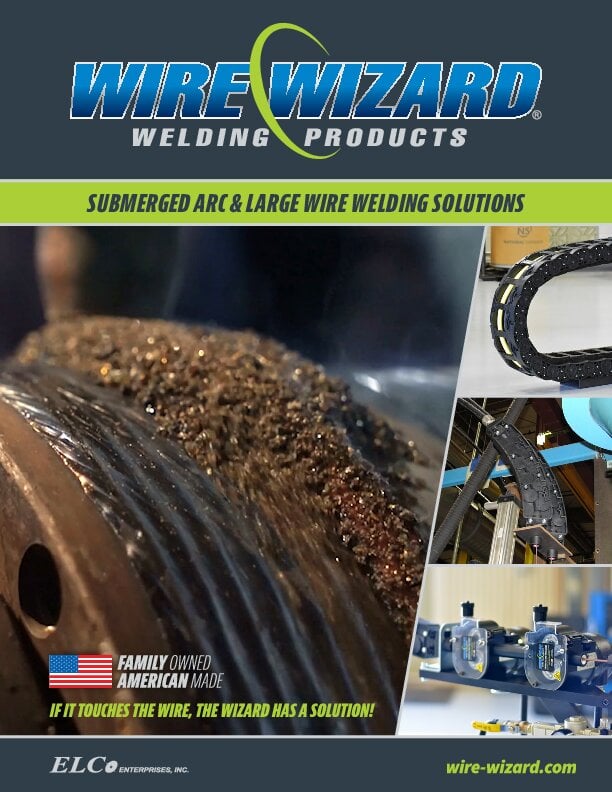

Submerged arc welding

We have various peripheral equipment for large diameter wires such as for submerged arc welding. |

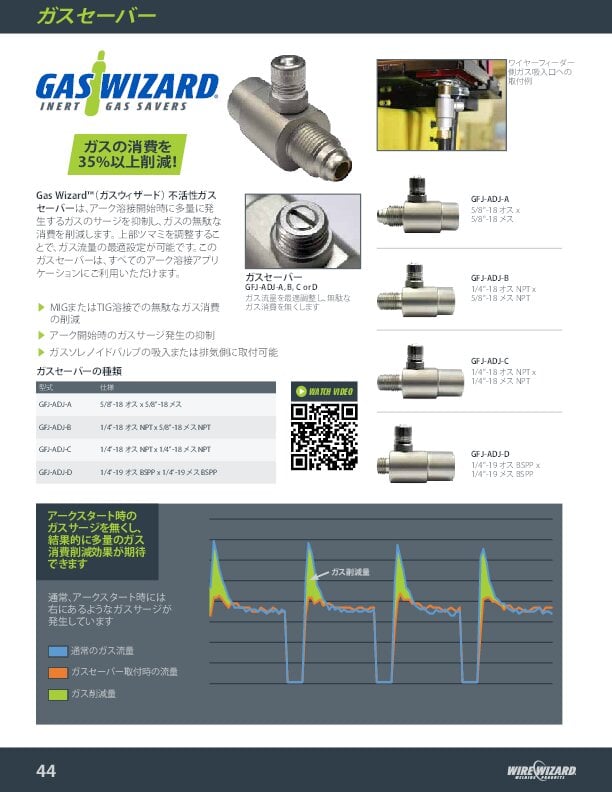

inert gas saver

This suppresses gas surges at the start of arc welding, resulting in a large amount of wasted gas consumption.

|